Cross Solenoid Valves With Ease

Cross Solenoid Valves With Ease

Let's delve into solenoid valves and how to switch them out efficiently to avoid any machine downtime. These valves conform to industry standards—like DO3, DO5, or DO8 sizes—making it easy to swap a valve in case of a machine being down.

Solenoid valves typically have two common electrical connection styles: a box style where you wire from the side with a cord grip or a DIN style where you directly connect individual connectors onto the coils.

The Information We Need

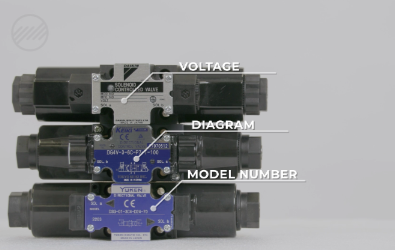

For successful valve crosses, provide us with a clear picture of the valve's nameplate displaying the part number, diagram, and voltage. Additionally, include a side picture for better understanding of the valve layout.

Customers can email All World customer service at customerservice@allworldmachinery.com and attach their pictures or call for assistance at 815-943-9111.

When replacing valves, remember that you don't always need an exact replacement of your old valve; most valves work similarly by moving spools using power. The key is ensuring that the valve spool operates the same and that when mounting, you align the tank (T) and pressure (P) sides correctly.

Using the Correct Placement

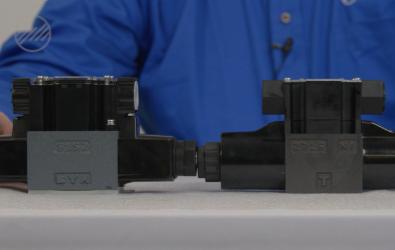

When looking at a solenoid valve, you may notice markings such as P, APB, and T on the casting body. The T signifies the tank side, while P indicates the pressure side. Additionally, there are A and B sides to consider when working with the valve.

When dealing with valve manufacturers, spool configurations may look the same, but the A and B coils are positioned on opposite sides. Focus on matching the T or P side of the new valve with that of the old one during mounting. This ensures correct installation without worrying about how the spool is identified.

Manifold Valve Stacks

When reinstalling valves on a manifold and unsure of their orientation, look at the P and T lines on the side of the manifold. The port on top of the manifold facing the P side is for the pressure line, ensuring correct positioning. Match the P side of the valve to the P side port for proper installation.

If you have additional devices in the stack and can't recall the setup, remember that on modular valves, the nameplate side is the P side of the modular valve. Ensure everything is mounted in the correct direction with P side of the manifold all the way up on the stack, and you're all set.

Depending on the type and age of your valve, you may encounter two signal wires and two common wires. Many modern valves come with a jumper on the common wire. If you don't need it, you can remove the jumper and connect the common wires individually or leave them tied together with the jumper – whichever method suits your needs.

In hydraulics, heat is a common concern. When pressurized fluid passes through a fixed orifice, heat is produced. If you're facing heat-related problems with your machinery, pinpoint the source of the heat. Is it the valve stack, the hydraulic pump, or a cylinder? Typically, heat generation signals a leakage issue between cylinder sides, causing overheating in the valve stack due to malfunctioning equipment. For preventive maintenance, identify and address the source of heat to fix existing problems or prevent future issues.

If you're struggling to mount a crossed over valve, check if you're matching the spool configuration correctly. Some manufacturers may flip the spool diagram, causing confusion. Valves adhering to DO3 standards are deliberately designed .75 of a millimeter off to prevent incorrect mounting. If you're still facing issues, try rotating the valve 180 degrees. Ensure that T aligns with T side, and P aligns with P side of the manifold for correct mounting. If you still not getting anything working on the device, make sure you are getting fluid to the valve in that stack and that your pump is not the issue.

All World understands the critical role that valves play in your operations. That's why we maintain an extensive inventory of valves, ready to meet your needs at a moment's notice. Whether you're dealing with an unexpected breakdown or routine maintenance, we have the expertise and stock to cross-reference your old valve and provide an exact match.

Our streamlined process ensures that we can cross-reference your valve swiftly, ship it out the same day, and have it delivered to you by the next day. This rapid turnaround minimizes downtime, getting your machinery back up and running with minimal disruption to your operations.

Should you need assistance, our dedicated customer service team is always on hand to support you. They will help you identify the correct valve quickly and guide you through the installation process, ensuring that everything runs smoothly.

Don't let a valve issue halt your productivity. Contact All World today and let us help you keep your operations moving efficiently.