Answering Your Common O-Ring Questions

Look anywhere in a manufacturing facility and you are bound to see them everywhere. The incredibly common sealing products used on everything from valves to pumps and hydraulic units—otherwise known as O-rings—seem straightforward. But don’t let their simple design fool you on machine tool applications. There are thousands of them, and you must find just the right size for your application. Ensuring a snug seal means protecting your most valuable assets. We are here to help you measure the O-ring, unravel the mystery behind the JIS and AS variations, and figure out the process of crossing the two. Let us guide you through the different material types and the importance of backup O-rings to avoid any “oh no” situations in sealing.

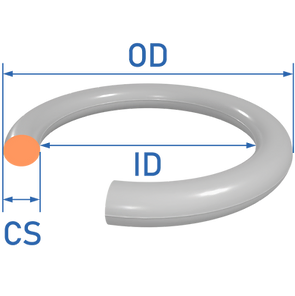

How Do I Measure an O-Ring?

There are three different dimensions to measure: the inner diameter (ID), the outer diameter (OD), and the width, or thickness, of the O-ring itself. You can obtain those measurements using a caliper or other tools. Make sure to lightly clamp the jaws of the caliper onto the inside or outside of the O-ring without compressing it. If you can provide two of the three dimensions, the third dimension can be determined.

What is the Difference Between JIS and AS?

Standard Japanese O-ring sizes are known as JIS, or Japanese industrial standard, and are unique to Japan’s automotive and manufacturing industries. JIS O-rings come in four sizes for different applications, such as “P” for dynamic sealing, “G” for fixed or static, “S” for special sizes, and “V” for vacuum flange applications. AS, for American standard, refers to American O-rings where they are most commonly the AS568 classification.

Oh Really, I Can Cross an AS to a JIS or JIS to AS?

If you can provide us with measurements of your O-ring and tell us about its application, we will be able to determine if the dimensions fall in tolerable ranges, and if you can replace your AS O-ring with a JIS or vice versa. Usually, a JIS and AS are interchangeable if the thickness is not a factor in sealing your application.

Do Material Types Matter? Oh Yeah, They Do.

There are three types of materials in O-rings. The 70-durometer O-rings are the most common and rated up to 3,000 psi. O-rings of 90 durometers are a slightly harder rubber version, and Viton O-rings are compatible with chemicals and oils and resist high temperatures up to 400° F. A simple trick for spotting a Viton O-ring is to observe its different sheen, its more soft and supple nature, or its blue or brown color, depending on the brand.

Do I Need to Replace My Back-up Ring? Right-o!

If you are replacing your O-ring, you must replace your backup ring. O-rings used in tandem with a backup ring help with retention and help prevent wear and tear if there are pinch points in a mobile application. The backup ring acts as a failsafe in applications which could result in the O-ring moving or slipping out of place. Be sure to replace your backup rings and keep them in good condition.

Oh Sure, Tolerance is Important.

Tolerance determines how much the O-ring can stretch or compress and still maintain its function. In some applications, the O-ring may need to stretch over a lip or be squeezed by forces to seal, and it must have a tolerance that will enable it to maintain its structural integrity.

Need Help? Come on O’ver!

We've got you covered! Our staff works with a wide range of customers having unique application needs and would be happy to help you find the right O-ring and answer any questions you may have.

At All World, we stock all P, G, and S series O-rings, the most common sizes of O-rings in manufacturing industries. While rubber is the most common O-ring material, we also have a growing selection of various other O-ring material types, such as 70 and 90 Buna, Ethylene Propylene or EP, Viton, and Silicon.

We have O-rings from 2-3 millimeters to several feet wide, and everything in between. For unusual applications, All World carries an O-ring cord allowing you to create a specialty-size ring to connect on your own. From skid loaders and tractors to manufacturing machinery, we provide a wide range of O-rings to ensure just the right fit for your application. Can we help you find the right O-ring? Oh, you better believe it!