Machine Accessories

Shop by Category

Hydraulic Pulling Power for Plastic Injection Molding

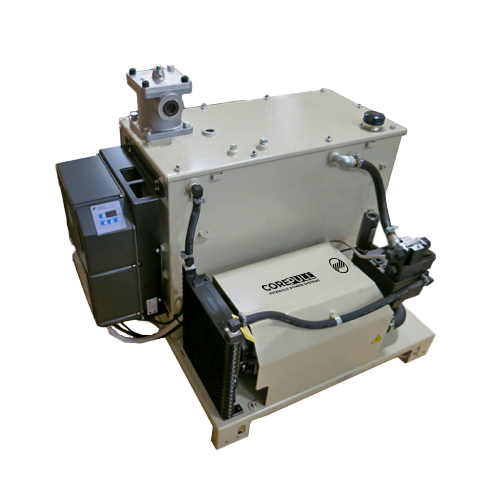

Pulling power built specifically for electric plastic injection molding machines. CorePULL® is custom engineered and assembled to fit your exact specifications with with smart pressure, level, and flow sensors that are IoT ready. Manifolds are available with up to 12 stations, with valve stacks on each station configurable to your project’s requirements. Utilize a wide range of programmable operating pressures and flows which are digitally controlled.

Quiet. Cool. POWERFUL.

In our world, every detail counts. Building customer-specific solutions demands precision. At All World, we take collaboration seriously.

Basic Features

Built specifically to handle plastic

injection molding for electronic injection

machines.

Small, compact design makes it easy to fit next to the machine during operation.

Quiet and cool operation at 60 to 69 dba, operating at room temperature, with no cooling water required for operation.

Fully customizable and programmable pressure switches, flow sensors, and valve stacks in any configuration or combination.

Save up to 63% on energy costs due to hybrid on demand features.

Control features that allow you to monitor and change pressure and flow, sequence valves,

or start and stop the unit on the fly.

Fluid Power

Endless Configurations

Can operate from 1 to 12 separate valve station configurations.

Super Speed

Higher volume flow rate than most conventional systems.

Hybrid Performance

Maintains low energy consumption, low operating temperature, and minimal oil usage.

Major Power

1,000 PSI to 3,000 PSI standard.

Forward Thinking

CorePULL systems are IOT ready hydraulic systems designed for the digital age, using the latest smart technology.

.png)

IOT Ready

Industry 4.0 capabilities with smart pump and smart sensors technology that allow for immediate monitoring and analytics.

Easy Integration

Simple connectivity into most machine tools, robotics, and controllers with multiple connectivity options such as IO, Modbus, or ethernet IP.

Plug & Play

Designed with M12 connection hubs and M12 connection cables that ensure quick assembly and customized diagnostics information.

Standard and Custom Options Available

EHU30R

- 7 gal/min

- Up to 1,000 PSI

- 3 1/2 HP

- D03 size valves

- 5 gallon reservoir

- Single pump system

SUT06D40

- 11 gal/min

- Up to 2,100 PSI

- 5 HP

- D05 size valves

- 15 gallon reservoir

- High/low system

Low Profile

- 11-21 gal/min

- Up to 3,000 PSI

- 5-9 HP

- D05 size valves

- 10-15 gallon reservoir

- Double pump system

SUT10D60

- 16 gal/min

- Up to 3,100 PSI

- 7 HP

- D05 size valves

- 25 gallon reservoir

- High/low system

SUT10D80

- 21 gal/min

- Up to 2,500 PSI

- 9 HP

- D05 or D08 size valves

- 25 gallon reservoir

- High/low system

SUT110

- 29 gal/min

- Up to 3,000 PSI

- 15 HP

- D05 or D08 size valves

- 50 gallon reservoir

- Double pump system

Lighting Fast Response

Quotes are typically completed within 24 to 48 hours and we stock all items for fast delivery.

Small size systems usually within 1-2 weeks, and larger systems within 3-4 weeks.

All quotes come with a concept hydraulic schematic for a visual representation

3-4 week lead times for delivery of units with 1-to-2-week deliveries on expedited projects.

Address

6164 All World Way

Roscoe, IL 61073

Phone

(815) 943-9111