Machine Accessories

Shop by Category

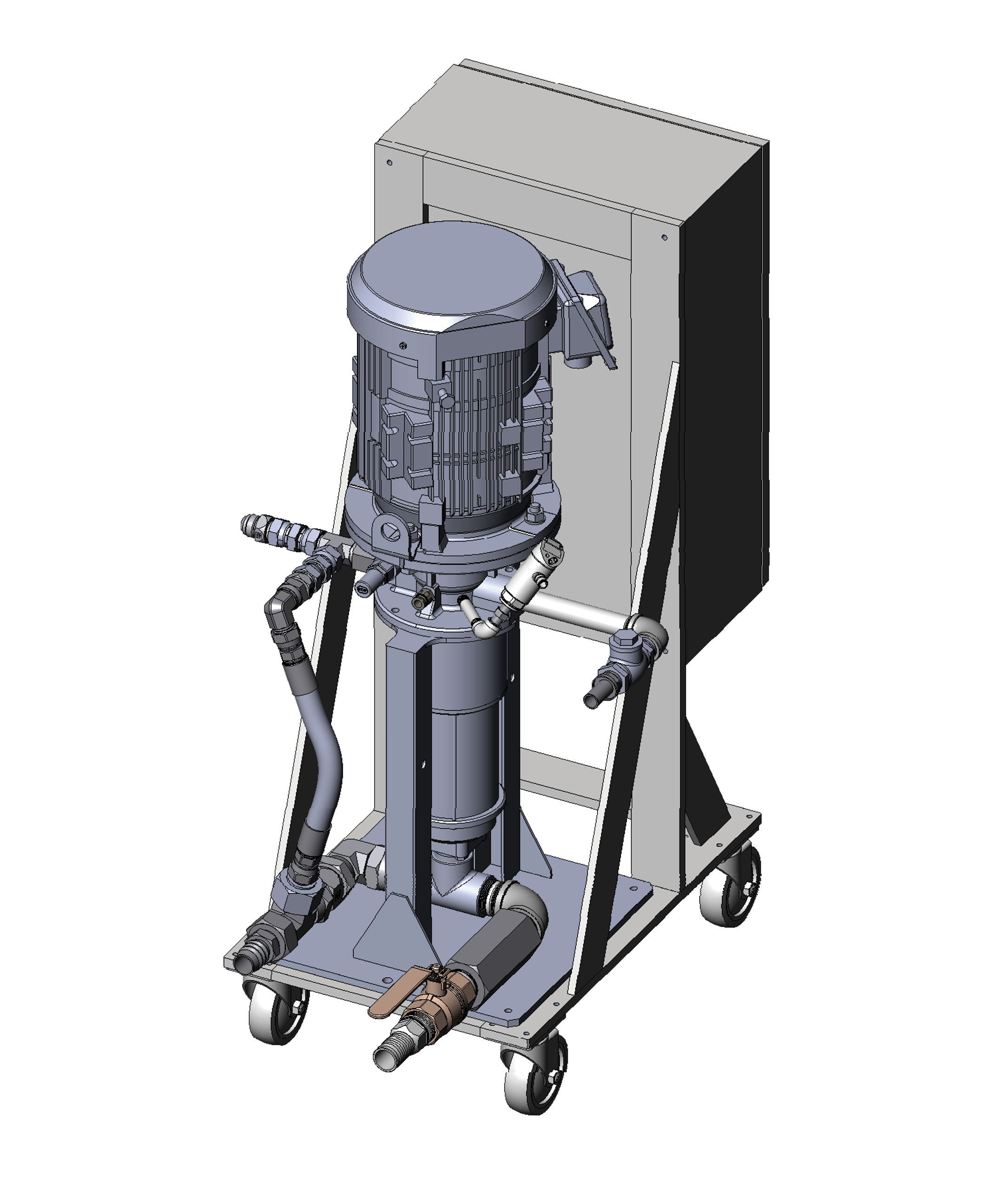

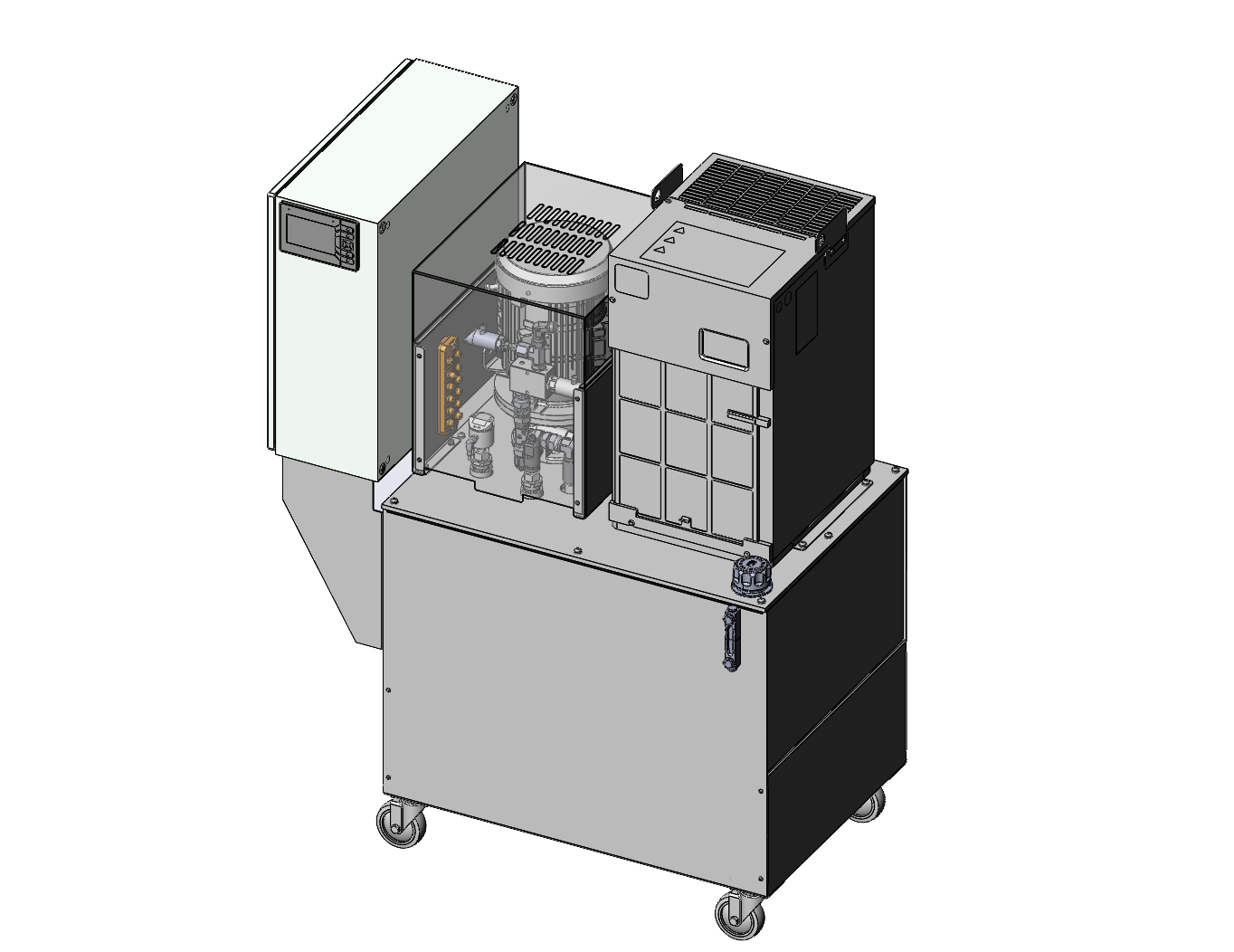

High Pressure Through Spindle Coolant System

Effective chip removal is essential for manufacturing tolerance. With customizable features for more precise machining and an automatic self-cleaning filter for less maintenance, SpindleSHOT® efficiently removes chips during deep drilling operations. SpindleSHOT effectively serves industries requiring high precision parts such as automotive, aerospace, and medical.

.png)

CONSISTENT. cONNECTED. PRECISE.

In our world, every detail counts. Building customer-specific solutions demands precision. At All World, we take collaboration seriously.Basic Features

Temp Control

Ensure temperature consistency with optional chillers. Maintain fluid temperature to within one-half of a degree C and keep it stable. Three chiller options are available, depending on the cooling capacity required.

Pressure Control

Experience unparalleled control with versatile pressure settings which can be fine-tuned to your application’s precise needs. Choose from customizable pressure settings ranging from 200 to 1,000.

System Monitoring

Monitor coolant temperature, pressure, and levels with an onboard control package. A user-friendly, pre-programmed human machine interface (HMI) comes standard with each SpindleSHOT model.

Clog-Free

Using centrifugal force coupled with turbulence, the NOP Coolant Unit YTH pump separates and removes contaminants through a mesh filter. The centrifugal filter system is designed to be clog-free, ensuring a steady flow rate and minimizing maintenance.

Self Cleaning

With a built-in cyclonic system and control, the SpindleSHOT self-monitors its own filter requirements and will do an automatic reverse purge to clean itself. Any contamination pulled into the pump is spun out of the coolant and directed to the drain port.

Low Maintenance

The automatic self-cleaning Turbulence™ filter eliminates the need for traditional bag filters. Whereas traditional CTS systems often require monthly bag filter replacements, the self-cleaning filter only requires a tank wipe down after around 6-12 months.

Forward Thinking

SpindleSHOT systems are IOT ready, designed for the digital age, using the latest smart technology.

Plug & Play

Built with IoT capabilities and multiple connectivity options, including Ethernet TCP/IP, Ethernet/IP, Modbus TCP, OPC UA, and CANopen, the controls seamlessly integrate into existing machines and facilitate remote system monitoring.

Knowledge Base

Access an array of user-accessible features through the intuitive human machine interface (HMI). View real-time diagnostics, access instruction manuals, and monitor the entire system's status all through the easy to use interface.

Immediate Action

The control package ensures optimal operation by monitoring coolant temperature, pressure, and levels, which helps in preventing overflow of the coolant tank. It also detects any filter blockages and automatically initiates a back flush.

Tank or Tankless Options

A basic tankless SpindleSHOT unit with filtration and pumping capabilities is available in an economy version for intermittent operational usage. Optional accessories include wheel kit and HMI.

Designed for regular use, the SpindleSHOT+ system includes a tank for higher volumes. Optional accessories include wheel kit, HMI, chiller, Royal Filtermist, Variaxe Oil Skimmer, stepped pressure control, and even multiple pump configurations.

Lightning Fast Response

Quotes are typically completed within 1 week and we stock all items for fast delivery.

All quotes come with a concept schematic for a visual representation

12-14 week lead times for delivery of units.

Address

6164 All World Way

Roscoe, IL 61073

Phone

(815) 943-9111