Shop by Category

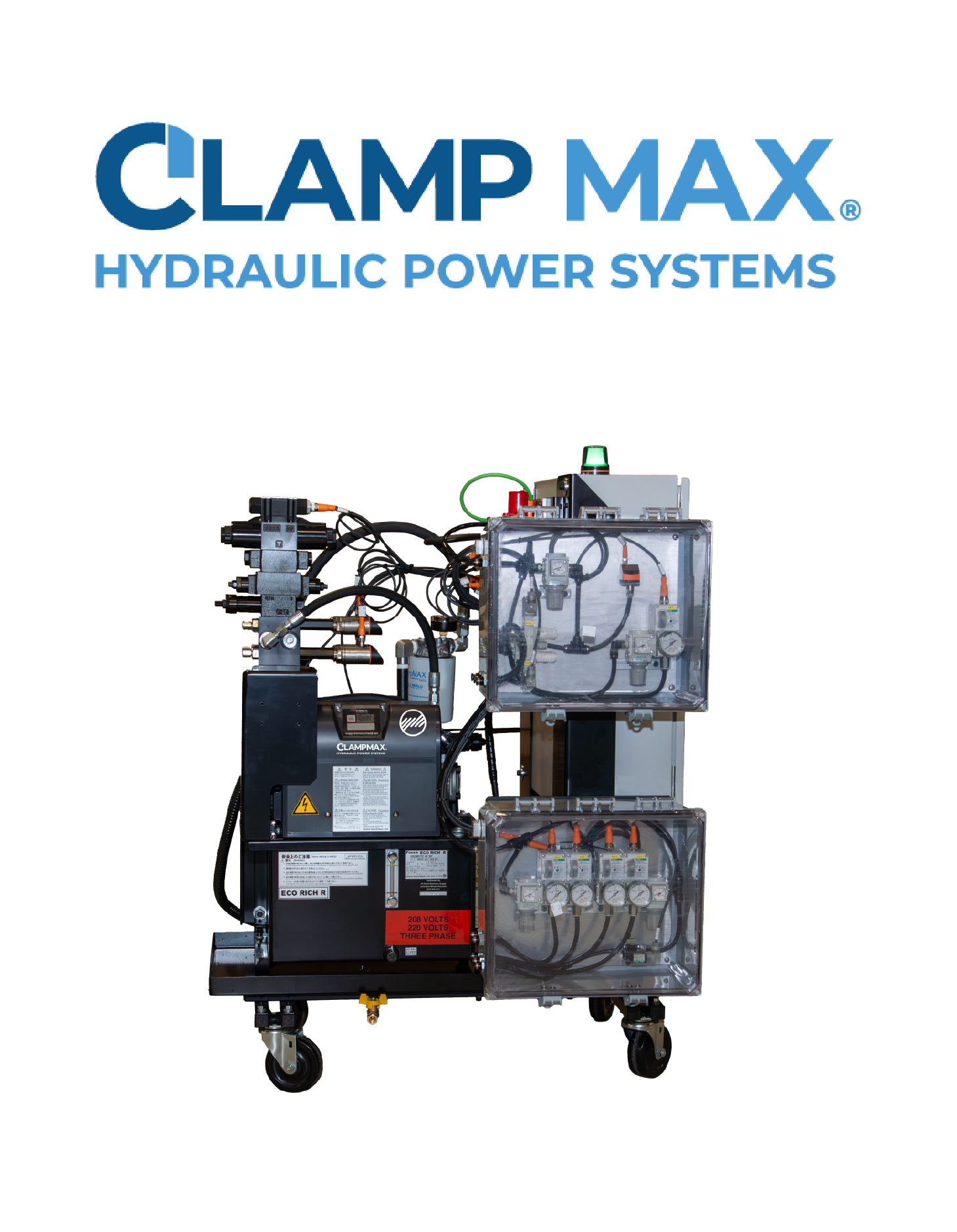

Integration for Robotic Workholding

Combining multiple processes into one system saves time, space, and resources.

When you are running a machine shop at full capacity, how do you safely and optimally transform your machining center into an automated powerhouse?

Transform your machine tool’s performance with All World integration services. Our team of engineers and field service technicians can enhance the performance, quality, and reliability of your CNC equipment, so that you can cut better quality parts with higher tolerances. We eliminate the complications and costs of multiple vendors by combining the design, manufacturing, programming, and installation of robotics and workholding equipment into one efficient and user-friendly package.

.png)

Integration Benefits

24/7 Operations

Robots enable factories to run continuously, making it easier to cover hard-to-fill shifts.

Increased Efficiency

With robots handling routine tasks, operators can focus on essential responsibilities, leading to a significant boost in overall efficiency.

Enhanced Safety

By taking over repetitive tasks, robots reduce the risk of injury and minimize the need for human intervention.

Expanded Capabilities

A robot arm can manipulate a CNC machine tool, achieving more complex and precise movements.

Built for Automation

Our experts manage each stage of your integration project, including planning, process designing, programming, and final inspection utilizing premium brands that you know and trust for IIOT solutions.

.png)

Solutions That Synergize

Lightning Fast Response

Full workholding project quotes are typically completed within a week, and we stock all items for fast delivery.

All quotes come with a concept schematic for a visual representation.

Projects can be expedited for quicker delivery.

Address

6164 All World Way

Roscoe, IL 61073

Phone

(815) 943-9111