Shop by Category

CorePULL® Accessories

Go big or go home! CorePULL® offers a wide range of accessories for you to make the most of your hydraulic power system. From a customized HMI display to air gap packages, CorePULL can meet the needs of any plastic injection molding application.

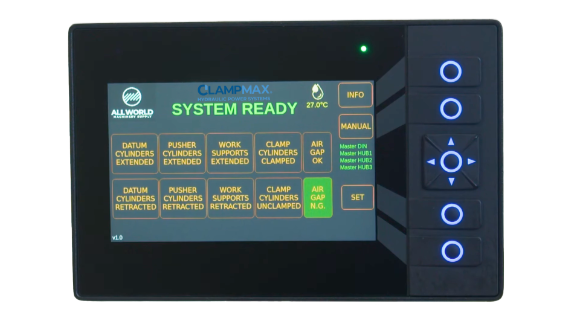

HMI DISPLAY

With the utilization of IFM PLC technology,our HMI package allows for easy monitoring of current real time condition status. This allows you to see what is actuated in real time, with the ability to make live adjustments to your pump, sensors, and switches. Always know your maintenance status with alarm display features that include alarm history, alarm descriptions, and suggested maintenance.

- Find your operation manual preloaded onto the display for easy access.

- The HMI connects to the control system with a simple ethernet IP connection using the standardized IFM smart hubs.

- Cycling the unit between step by step movements for setup and maintenance purposes or automatic modes for machine tool operation on the HMI interface can be done with a single keystroke.

- Want to operate the HMI from the PLC instead of mounting to the unit? Easily place you mount on your PLC using the standardized magnetic mount adapter and retractable cable system.

REMOTE KEYPAD

Replaces keypad on unit

and can be mounted

horizontally or vertically.

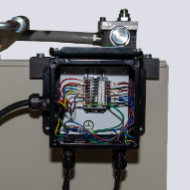

ECONO J-BOX

Makes the communication

interface with your injection

molding machine’s controller

a plug-and-play feature.

HEAT EXCHANGER

Remove heat from oil in the injection molding machine to ensure part consistency.

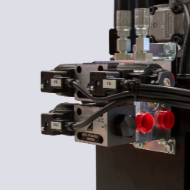

VALVE GATE

Support consistent control. Eliminate the need for cooling and trimming of runners to

reduce cycle time and improve part quality.

WHEEL KIT

Wheel kits make the transportation of your customized unit a breeze allowing for maximum flexibility of placement so that you can take it anywhere safely and quickly.

ACCUMULATOR

Bladder accumulator with 800 PSI, and a mounting plate. Isolation

mounting clamps are

included with dual port

flow control module.